MIL-PRF-2818D

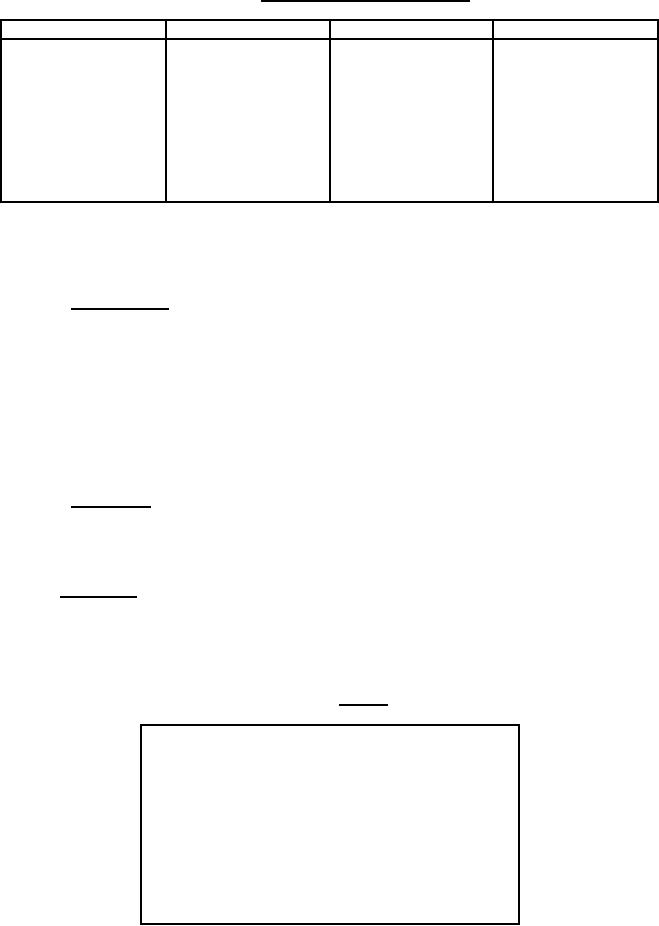

TABLE IV. Sampling for examination and test.

Reject 1/2/3/

Lot size

Sample size

Accept

2 - 15

2

0

1

16 - 25

3

0

1

26 - 90

5

0

1

91 - 150

6

0

1

151 - 280

7

0

1

281 - 500

9

0

1

501 - 1200

11

0

1

1201 - 3200

13

0

1

3201 - over

15

0

1

1/

All defective items must be replaced with acceptable items prior to lot acceptance.

2/

Inspect sample size until reject criteria is reached. If reject criteria is reached, reject entire lot.

3/

Reject lots may be screened and resubmitted for inspection and test.

4.3.2 Noncompliance. If any of the material tested fails to meet the requirements of Table III, the

contractor shall notify the contracting activity and the cognizant inspection activity of such failure and take

corrective action on the materials or processes, or both, as warranted, and on all units of product which can be

corrected and which are manufactured under essentially the same materials and processes, and which are

considered by the inspection activity to be subject to the same failure. Acceptance and shipment of the product

shall be discontinued until corrective action has been taken, inspections shall be repeated on additional units (all

tests and examinations, or the test which the original unit failed at the option of the contracting activity). Final

acceptance and shipment shall be withheld until inspections have shown that the corrective action was successful.

In the event of failure after re-inspection, information concerning the failure shall be furnished to the cognizant

inspection activity and the contracting activity.

4.3.3 Certification. The material shall meet the requirements for fire resistance, thermal conductivity,

resistance to vibration and maximum exothermic temperature rise. A certificate of compliance is not acceptable

in place of a first article test for resistance to vibration, thermal conductivity, and maximum exothermic

temperature rise but may be acceptable for the fire resistance test (see 6.3).

4.4 Examination. When required by contractor or purchase order (see 6.2), blankets selected in

accordance with the sampling guidance provided in 4.3.1 shall be surface examined and measured to determine

conformance to the requirements of this specification which do not require tests. Defects shall be as described in

Table V. Any blanket selected for examination which contains one or more visual or dimensional defects shall not

be offered for delivery.

TABLE V. Defects.

Jagged ends of mesh wire, tie wire, or expanded metal.

Length not as specified (3.4).

Width not as specified (3.4).

Thickness not as specified (3.4).

Spacing of tie wires not as specified (3.5).

Tie wires not securely attached.

Mesh wires not properly spaced.

Expanded metal broken.

Supporting members not specified.

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business